PRODUCTION

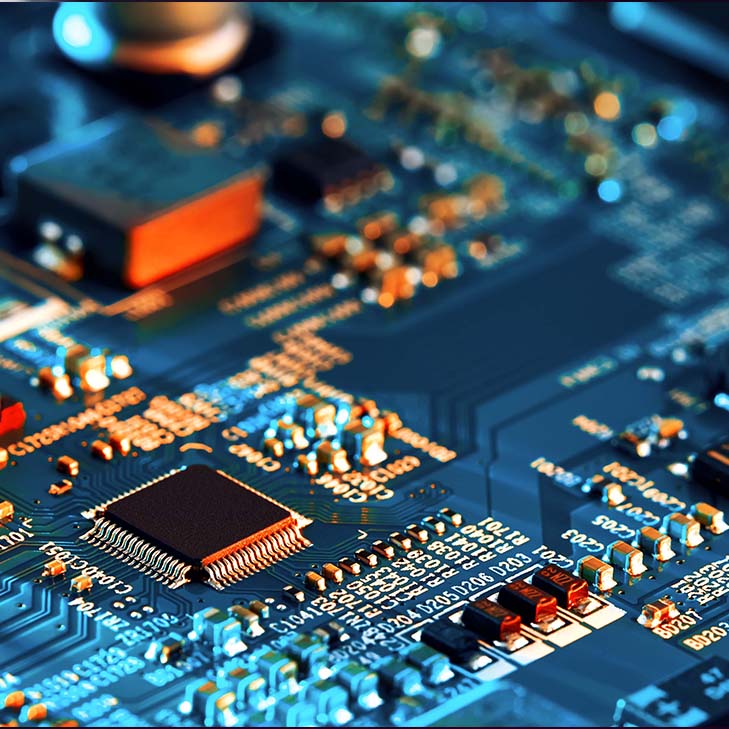

Thanks to the acquired know-how of our company, and our advanced equipment and machines and qualified personnel, we can guarantee a high level of competence and reliability in the production process.

We specialise in the production of electronic boards, with both traditional PTH and SMD component technologies, with automatic or manual assembly process. G.R.ELETTRONICA implements a production organisation for processes with the monitoring of the same in real time. All production is subjected to functional and visual tests according to the control and verification plans agreed with the customer.

We are able to provide finished or semi-finished equipment, in which the boards we produce are mounted, managing plastics, mechanical electrical parts, plants etc.

ORDER

MANAGEMENT

The management of orders uses a computer system that defines the production plans with all the stages of processing and the lists of components used.

The technical documentation regarding the production process is managed by computer; each operator has a terminal for access to the centralised technical documentation, to support its specific activity.

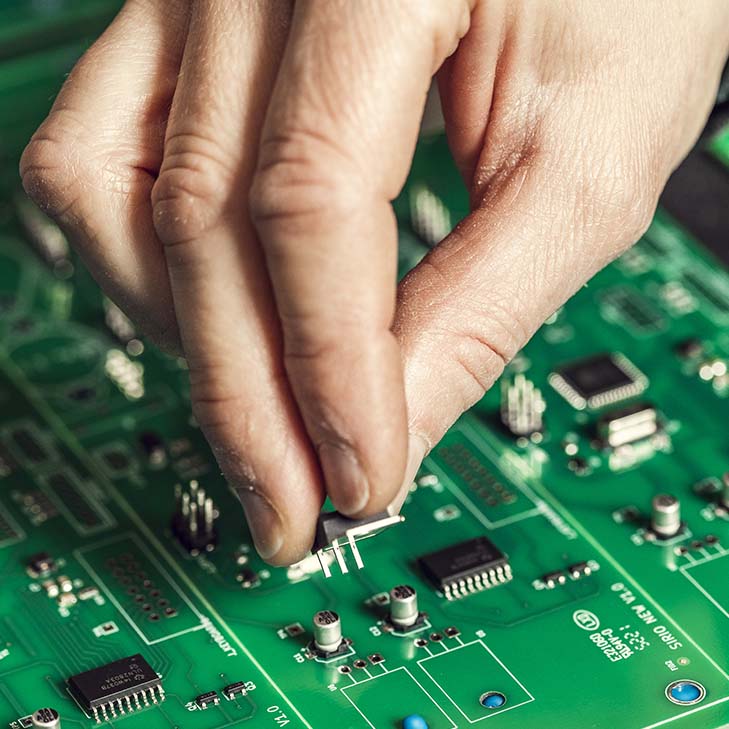

PTH COMPONENTS ASSEMBLY

PTH components are handled manually by specialised personnel for assembly and finishing touches.

The boards we produce can be welded manually or with wave welders using LeadFree “green” materials according to RoHS regulations.

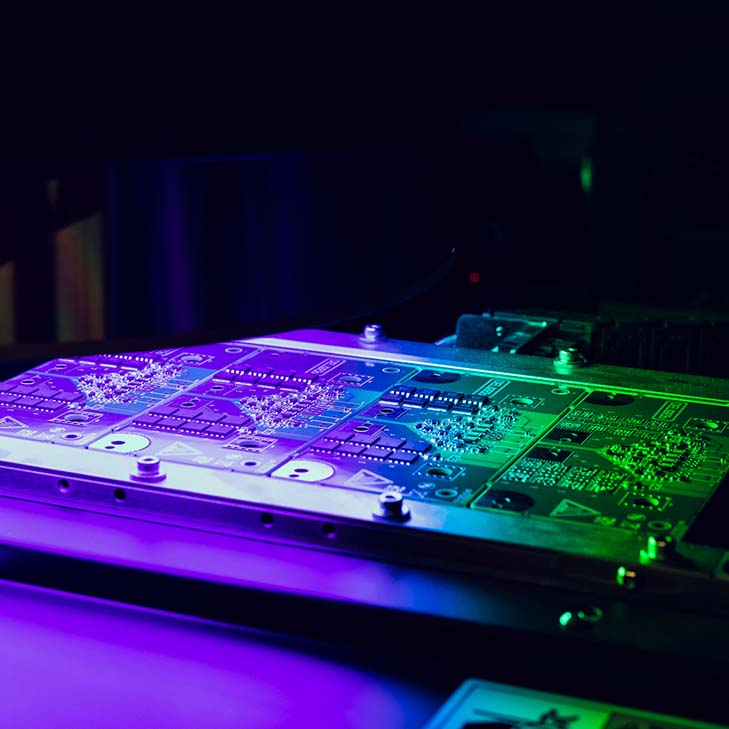

SMD COMPONENTS ASSEMBLY

During the loading phase, all components are checked and labelled to ensure traceability and correct assembly.

Production is carried out using an automatic production line with the latest generation positioner machines, which offer excellent flexibility and are ideal for diversified productions, from prototype to series production.

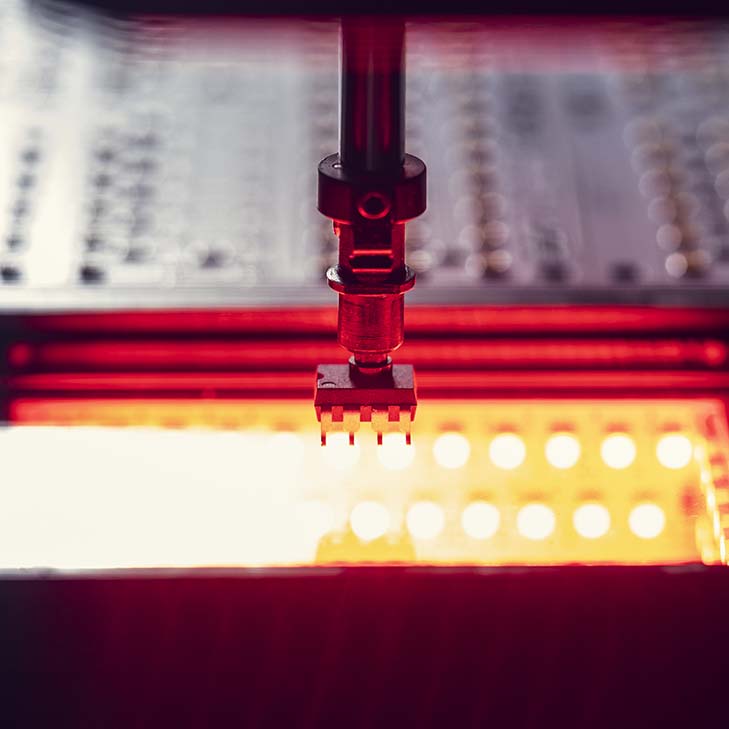

WAVE WELDING

SELECTIVE WELDING

G.R. Elettronica has two types of welding machinery for THT components.

- Automatic wave welding machine

Wave welding takes place automatically through the passage of the PCB on the tin wave.

- Selective welding machine

Selective welding is used for welding specific electronic components on a printed circuit board, leaving other areas of the board unchanged.

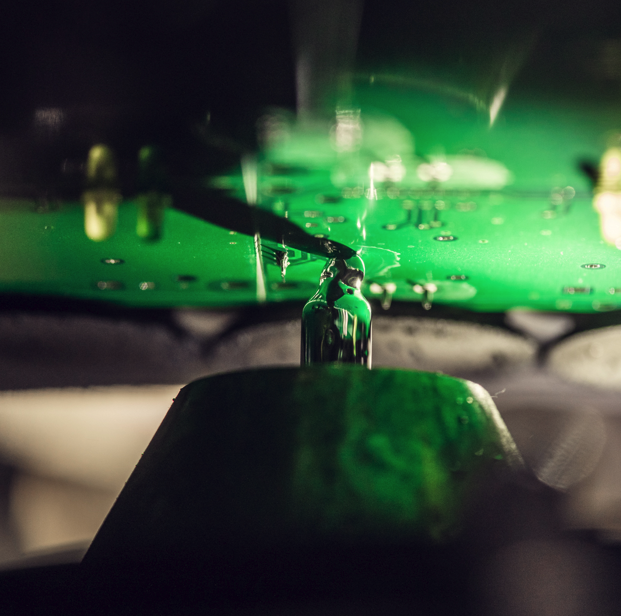

TESTING and

quality control

The constant monitoring of the production processes and the control at the end of the cycle allows us to ensure the conformity of the product to current specifications.

G.R. ELETTRONICA carries out a verification and/ or testing on 100% of the boards produced.

The correct functioning of the production process is guaranteed thanks to the optical inspection performed either by an operator or with Automatic Visual Testing (AOI), carried out during the assembly, welding and end-of-working processes.

The correct functionality of the product is guaranteed, with Functional Testing of the cards and equipment made, following the established procedures and using simulators and dedicated plugins.

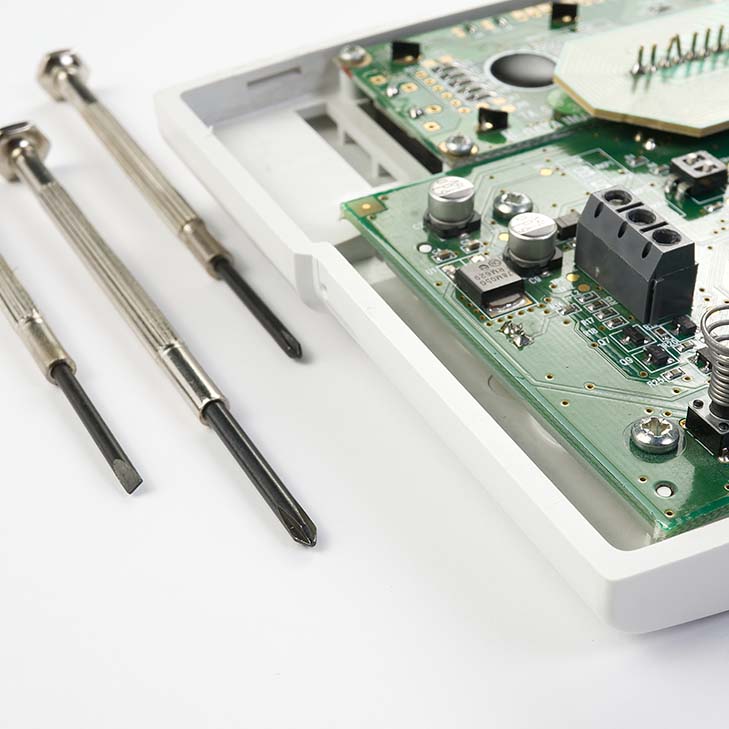

ASSEMBLY OF

FINISHED PRODUCTS

G.R. ELETTRONICA has the ability to carry out the assembly of electronic products according to the customer’s requests, be it a semi-finished product or a finished product.

Our qualified personnel allows us to operate on different types of products, treating mechanical parts, plastic housings, electrical parts, cables, etc. which together with the electronic cards we produce, constitute the product to be manufactured.

To ensure the conformity of the product to current regulations,functional and/or instrumental checks are carried out, such as: calibration and/or calibration with functional tests and electrical measurements.

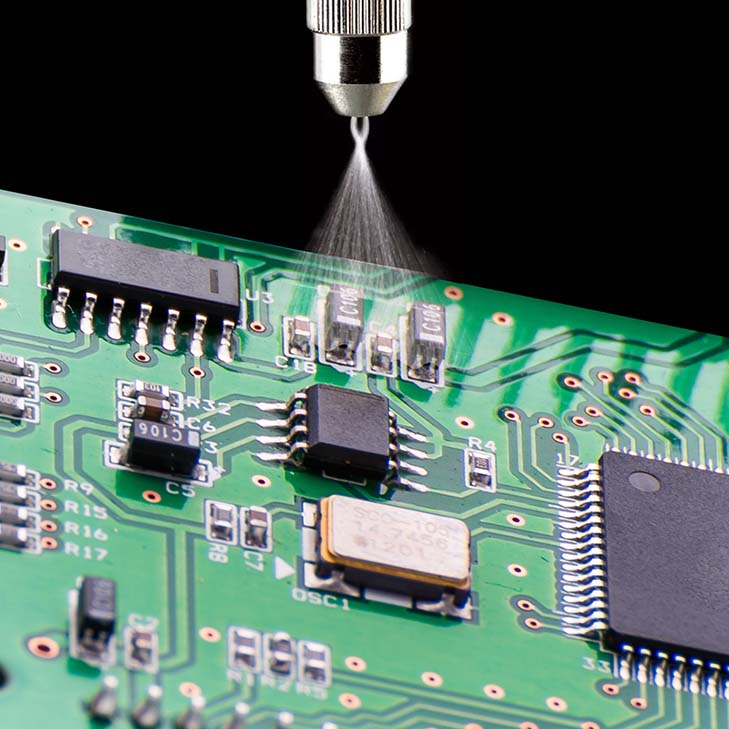

ELECTRONIC BOARD

FINISHING

In order to prevent the degradation of products by atmospheric or chemical agents, G.R. ELETTRONICA can perform the tropicalization of electronic boards, through a low-thickness surface coating of silicone resin.

Where it is necessary to improve the protection and resistance to mechanical shocks or vibrations (automotive or hostile environments) it is possible to carry out the complete resination of the electronic boards (potting) in appropriate casings.